SEO Focus Keyword: self-centering vise CNC

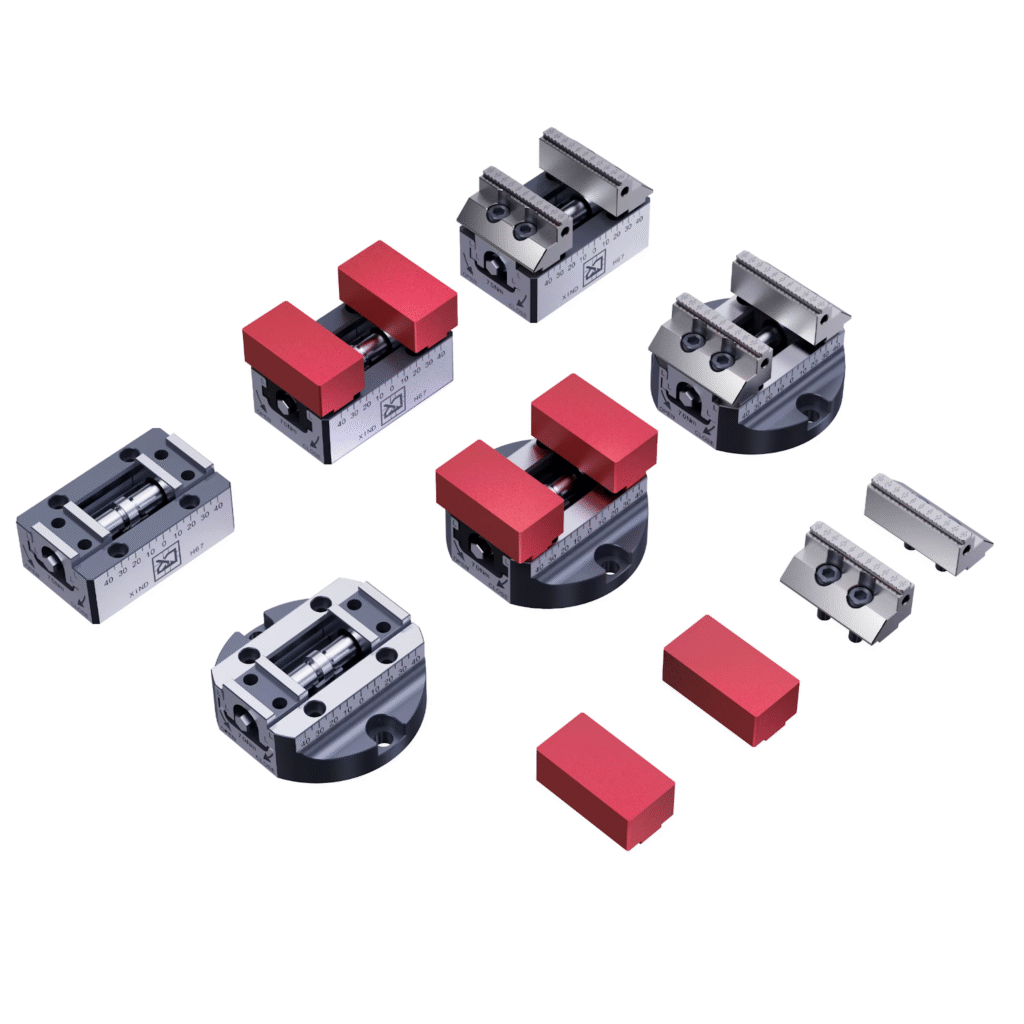

Meta Description: Compare H54 vs H67 vs H90X self-centering vises—repeatability, material suitability, jaw styles, and how they fit into EROWA/3R workflows.

Self-Centering Vises Are Trending for One Reason: Repeatable Symmetry

If you machine small to mid-sized parts, a self-centering vise can be a productivity multiplier. Instead of chasing alignment every time you load a part, you clamp from both sides symmetrically and reduce the need for constant re-indicating—especially on parts where centerline consistency matters.

But not all hydraulic vise are built for the same workload. In practice, your choice should be driven by:

- repeatable positioning accuracy,

- the materials you cut (aluminum vs steel),

- jaw interface and customization,

- compatibility with quick-change positioning systems.

Let’s break down three models often discussed together: H54, H67, and H90X.

1) H54: Affordable, System-Compatible, Best for Softer Materials

The H54 is presented as an affordable self-centering vise designed for compatibility with EROWA and SYSTEM 3R zero-point positioning systems, with repeatable positioning accuracy reaching 0.03 mm.

The key limitation is clearly stated: it’s mainly suitable for processing soft materials, and it is not recommended for steel parts.

Who should pick H54?

- Shops focused on aluminum, plastics, softer metals

- Prototyping environments that value low cost and fast setup

- Anyone wanting compatibility with common zero-point ecosystems without overbuying for heavy steel cutting

Jaw flexibility

The description lists multiple jaw options including serrated jaws, extended serrated jaws, high serrated jaws, and shaped soft jaws.

That jaw variety is often the difference between a “5th axis vise” and a “daily driver.”

2) H67: Higher Precision, Hardened for Tougher Work

The H67 description emphasizes that it is precision ground in all directions, with repeatable positioning accuracy reaching 0.02 mm.

It also specifies alloy steel construction with heat treatment enabling hardness of HRC58–62, and explicitly notes the vise can support processing hard materials such as steel.

Who should pick H67?

- Shops cutting steel regularly

- Users who need tighter repeatability than 0.03 mm

- Anyone trying to minimize deflection risk under heavier cutting loads

Jaw interface

The H67 description calls out 60° serrated dovetail jaws and special-shaped soft jaw options to match different processing needs.

A dovetail jaw interface is attractive because it can improve jaw security and reduce jaw lift tendencies compared with simpler designs.

3) H90X: Same Precision Class, More Options and Capacity Feel

The H90X is described similarly: precision ground, repeatable positioning accuracy 0.02 mm, jaw options (serrated or shaped soft jaws), alloy steel with hardness up to HRC58–62, and suitability for steel.

Where H90X typically earns attention is flexibility in variants/options (the product lists multiple vise and jaw configurations).

In many shops, that matters because you want to tune jaw height, clamping reach, or mounting strategy for specific part families.

Who should pick H90X?

- You want 0.02 mm repeatability and steel capability

- You expect to standardize on one vise family but need multiple configurations

- You are building a modular fixturing ecosystem across job types